Natural Cricket Surfaces

Design | Construction | Maintenance

The management of fine turf cricket tables is in total-play’s D.N.A. Managing Director David Bates was Head Groundsman at Northamptonshire C.C.C. and Chairman of the First Class Groundsman Committee before establishing the company and is also a trainer and pitch advisor for the Grounds Management Association, previously known as the Institute of Groundsmanship (IoG).

Backed by an experienced in-house workforce and an extensive range of state-of-the-art, laser-guided ground management and maintenance equipment total-play offers a ‘one-stop shop’ for clubs’ natural cricket; from designing and building new grounds to supporting ongoing maintenance and specialist table construction works.

We have helped numerous clients across the U.K. playing at everything from grassroots to first-class level ensure their fine turf cricket tables are fit to perform.

total-play – Natural Cricket Works:

Of all sports surfaces, natural cricket pitches are notoriously challenging to build and maintain. While non-turf cricket pitches have, over the years, come on leaps and bounds and offer a great alternative for both match play and practice, for many players, nothing beats playing on a well-maintained natural turf cricket pitch.

In an ideal world, a natural cricket pitch would be a solid block of clay loam – hard and at the correct moisture content to give the ball a true surface with the pace and bounce required for the modern game.

“The best pitch preparation techniques cannot overcome a weak profile. A weak profile can contain one or all of the following features, an organic layer at the surface, limited root density, layering or a low strength soil. The secret to a great cricket pitch is its profile.” David Bates – Director, total-play Ltd.

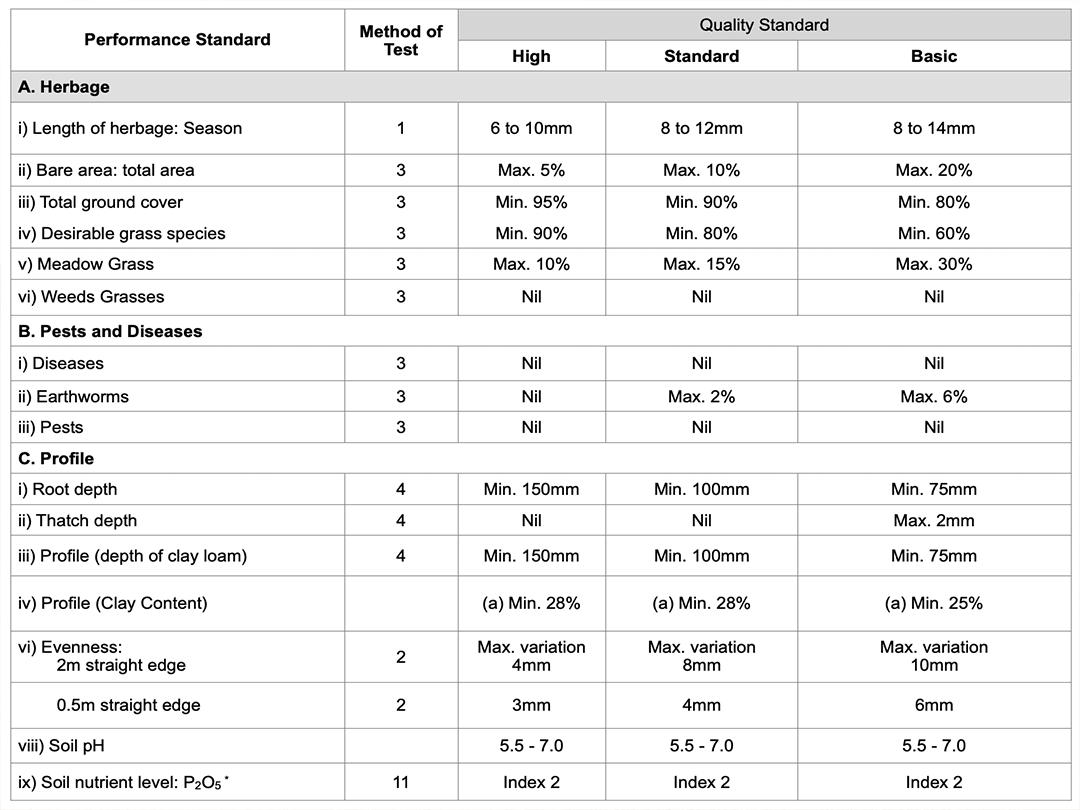

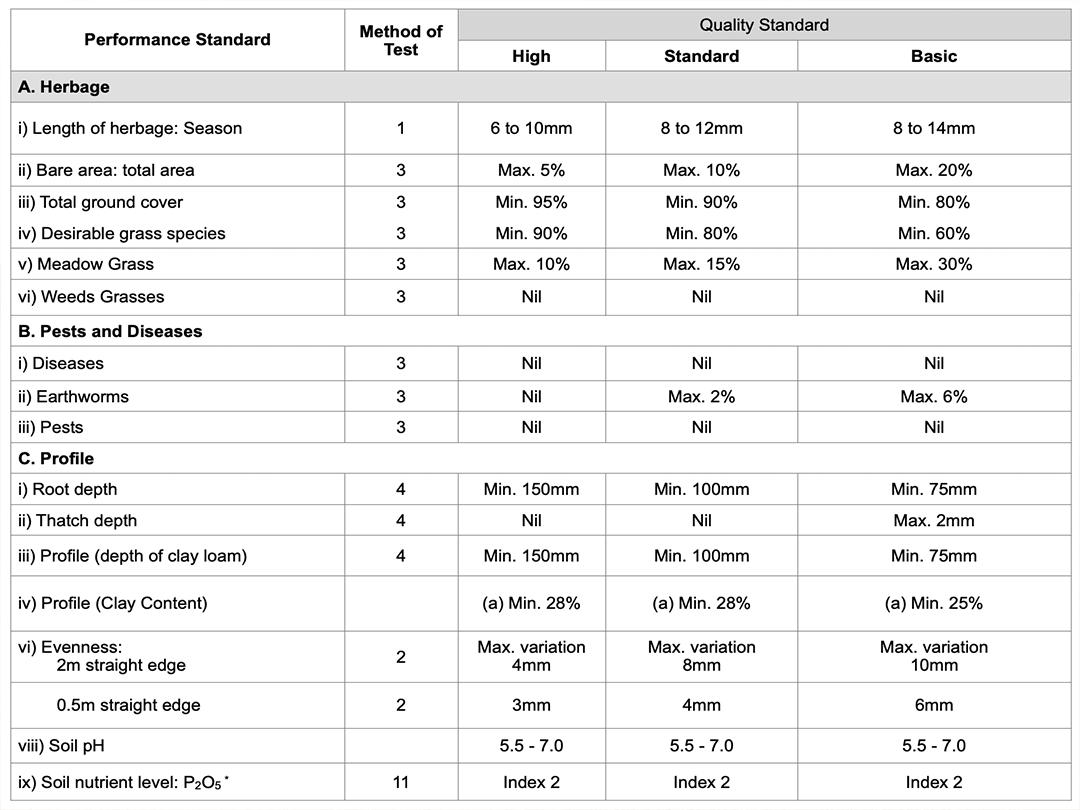

When constructing and maintaining a cricket ground, as part of its remit to raise standards across all areas of the game, the England & Wales Cricket Board (E.C.B.), in connection with the Grounds Management Association, has published rigorous Performance Quality Standards (P.Q.S.). These performance parameters help to design and benchmark grounds, outfields and tables. The performance standards include pitch dimensions, orientation, gradients, surface uniformity, grass sward etc.

The E.C.B. document’ TS4 – Recommended Guidelines for the construction, preparation and maintenance of cricket pitches and outfields at all game levels’ outlines all of these in detail.

The construction of a new cricket table from scratch requires expert input from the outset, from deciding the processes and timescales required for works and establishment of a playable surface to finer details like selecting the optimum materials based on the geography of the site and the native soil type. For example, the ‘Full Construction’ of a natural turf cricket pitch incorporates a gravel raft, building layer and loam. In contrast, the ‘Profile Construction’ of a natural cricket pitch uses imported loam directly on the existing soil base.

‘End of Season renovations’ or ‘Annual Maintenance’ works are completed following the end of the playing season. They provide the foundation for the next season’s playing surface and are vital. The most important part of the year for cricket groundsman is once play stops. The only real chance every year to carry out essential renovation works. To undertake ‘Surface Restoration’, ‘Annual Maintenance’ & ‘Profile Regenerations’ works. Do not leave this works too late to plan. Instead, get everything in place so work can start once the ground is free.

Please see the ‘T.P. Natural Cricket Table Processes’ document. It outlines the four possible operations available to every cricket table.