Artificial Cricket Pitch Maintenance

Advice – Guidance

Compared to a natural turf cricket surface, artificial cricket pitches require very little maintenance. However, to fulfil the true potential of the artificial cricket pitch, regular maintenance or up-keep is still required.

The main objective is to complete regular inspections and maintain the facility in accordance with the England & Wales Cricket Board (ECB) ‘TS6’ document.

total-play’s range of ECB approved artificial cricket pitch systems, tp365, tp5t and tpb1, incorporate the highest specification of components to provide longevity and performance. As such, the system in normal weather conditions requires NO rolling or watering.

However, there are a key series of maintenance tasks that should be carried out on the surface to ensure maximum lifespan and performance.

Keeping the artificial cricket pitch surface clean and free from contaminants is required maintenance and should be carried out regularly.

Contaminants come in the form of leaves, grass, moss, soil and algae. To protect the aggregate base from contamination, it is vital that the playing surface carpet pile does not retain these materials. Also, keeping the surface clean reduces the risk of trip hazards.

The removal of debris, such as leaves and other organic material, can be completed using a powered blower, a hand brush or a powered brush.

Contaminants should not be allowed to remain on the artificial cricket pitch for any length of time. They will rapidly rot down and encourage growth of moss and algae, which will result in a slippery and dangerous surface. Dirt, combined with the loss of pile height in the carpet due to wear, can become a real health and safety issue.

The infestation of weeds at the edge of an artificial cricket pitch is not uncommon and again, this is something that clubs can deal with in-house. Weeds or grasses can be ‘sprayed off’ using a commercial, household, total weed killer with ‘glyphosate’ as an active ingredient.

All total-play’s ECB approved artificial cricket pitch systems carry comprehensive and generous warranties. They are designed to offer clubs a sound investment, provided that the recommended maintenance tasks are carried out in the correct manner and recommended timescales.

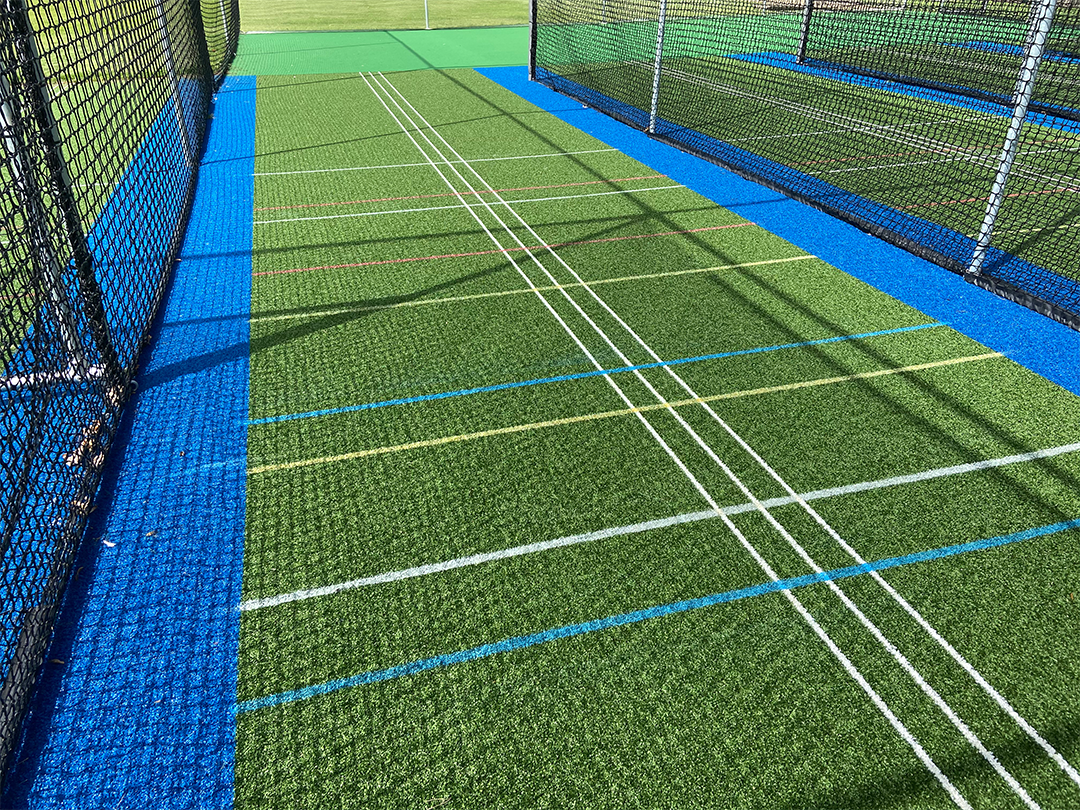

The high wear areas (Batting & Bowling Creases) will be the first to start showing signs of wear and tear.

Excessive wear to the carpet may result in a loss of traction or grip, and therefore pose the possibility of slipping. Regular inspections, paying special attention to the batting and bowlers’ ends are essential.

Check that the carpet fibres have not folded over and lost their structure. This can be completed using a stiff broom to brush the areas. The batting crease is a ‘high impact area’ and should be monitored carefully by the client.

Another way to prevent excessive wear is to discourage ‘bat tapping’, as the repeated action of bat striking the ground will inevitably create a depression in the base construction and eventually wear out the playing surface carpet and shock pad.

It is also important to note that the majority of all artificial cricket pitches are not designed for spiked footwear, with the exception of our TP Spike Pro System. Therefore, soft soled/rubber cricket shoes should be used.

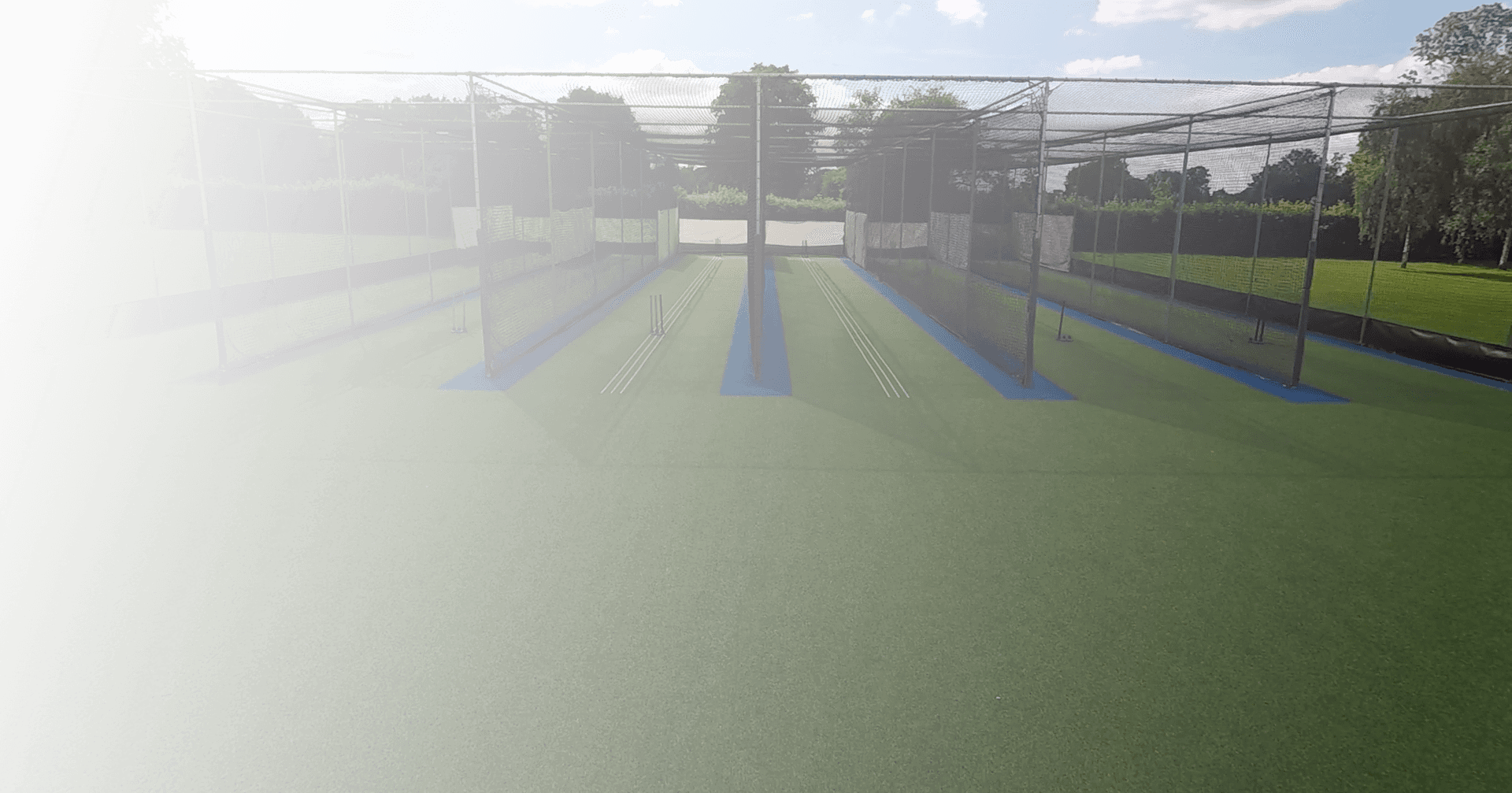

When a new artificial cricket pitch is installed, whether the surface is an artificial cricket match pitch at the side of the square, or an outfield artificial cricket net facility, it is constructed to perform to the standards set out by the ECB. Surface levels are critical, providing a consistent ball bounce and player comfort.

Surface levels will change with climatic conditions and usage. The higher the usage, the greater the wear will be on the artificial cricket pitch carpets, shock pads and the base construction. Excessive use of bowling machines dramatically increases the usage levels, shortening the lifespan of a lane compared to normal play.

However, any loss in surface levels can be solved by standard maintenance works by a total-play installer.

Undertake regular safety inspections of netting and steelwork systems.

Complete the following works as required: