For many years, the artificial or non-turf cricket pitch (NTP) has been a huge benefit to schools, clubs and the professional game.

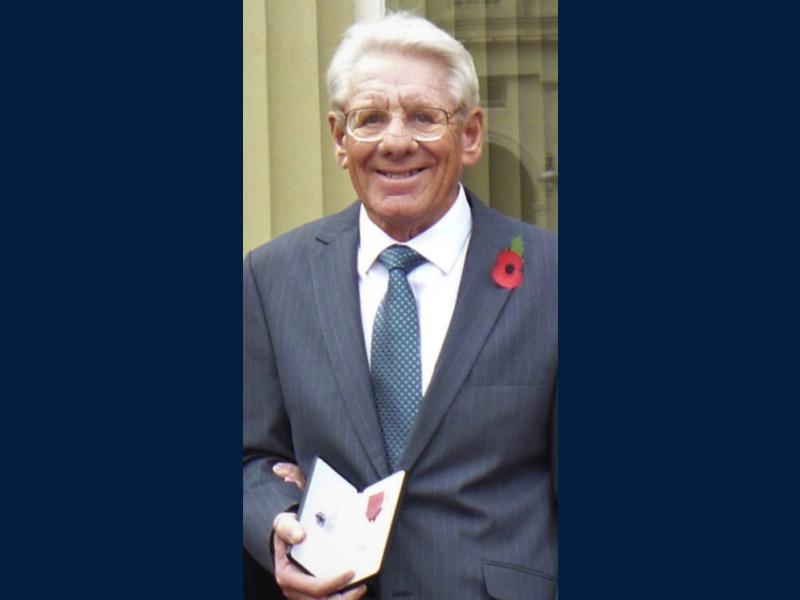

The original designer and creator, Mr Peter Dury, deserves credit for his efforts and foresight in the development of all-weather cricket playing surfaces. The game and the industry owe him a huge debt. However, it would also be fair to state that, from its original development, both materials and systems have evolved significantly over the past forty years.

External link : ECB pays tribute to Peter Drury Snr MBE

Like in life, people’s expectations and requirements have changed over time. For example, in the early days of artificial cricket pitches, cricketers were delighted to simply have a ‘batting end’, enabling some practice in unfavourable weather conditions. In the modern era, huge bespoke facilities hosting multiple lanes are required to fulfil both usage and health & safety requirements.

Performance expectations have also changed in line with the fast and hard-hitting modern game. More than ever, cricketers want the bat to dominate the ball and produce higher-scoring games. Moreover, short formats of the game promote talented ball strikers who need – and expect – a consistent surface.

At grass roots level, a huge majority of cricket is played in the park environment. Local councils aim to provide open sites for cricketers to compete at any time, rather than just structured league games at the weekends. However, with most local services facing financial restrictions, many natural cricket tables have not been maintained, making them unusable. To try and compensate for the reduced numbers of natural cricket tables, local councils, in connection with the England & Wales Cricket Board (ECB), are trying to introduce more non-turf match pitches to open parks and schools.

An artificial cricket ‘Match Pitch’ is generally placed within or at the edge of an existing natural table or as a standalone facility within an open grassed area which acts as an outfield. Match pitches are currently constructed at 2.74m wide (9ft) wide with lengths starting from 24m (78ft) for juniors under 12 years old, and up to 32m (105ft) for Centres of Excellence. The most common installation length is 30m (98ft), the ECB minimum standard for recreational/club usage. Since the invention of the NTP, dozens of unique designs/types have been brought to the market, with up to approximately twenty systems to date gaining ECB Design Approval Status. total-play Ltd has developed, to date, six of these ECB-approved system designs to reflect different client needs and budgets.

A ‘Practice Facility’ is generally placed at the side of a cricket outfield or, more commonly, entirely off the playing surface. A practice facility consists of a number of artificial cricket pitch lanes enclosed by a netting system, providing a safe and consistent space for bowlers and batters to practice their craft without the need for support from fielders. The original ‘cricket nets’ started as a single, natural turf batting end with a simple netting system held up by wooden guide poles. The practice facility then started to evolve, firstly by adding a bowling end and then by the replacement of the internal natural grass area with artificial fill-in sections. The size and type of systems also have developed with the ability now to have ‘open’ and ‘enclosed’ practice areas.

Open facilities are typically no shorter than 27m, meaning the bowler’s run-up will be from a natural grass area. In addition, the netting system covers multiple lanes no shorter than 18.3m and must include a roof net. Therefore, in an open system, the ball can escape the system and can potentially move between lanes whilst the bowlers’ run-up is on grass.

Enclosed facilities are fast becoming the preferred choice of clubs and schools at all levels. They are typically no shorter than 33m, allowing the bowler an 11.5m run-up on artificial turf. In addition, the netting system is longer per lane and totally encloses the facility, preventing a well-struck ball from leaving the system. Finally, the lack of a natural area makes enclosed facilities lower maintenance and means the system can be used anytime.

Selected Comments are taken from the England & Wales Cricket Board document –

‘GUIDANCE NOTES FOR THE PROVISION AND INSTALLATION OF NON-TURF CRICKET PITCHES AND NET CAGE FACILITIES’

A Non-Turf Cricket Pitch or Facility is a pitch or facility that does not support vegetation and is designed to function without vegetation. The bulk of the research on the current range of non-turf pitch systems (NTPs) was undertaken between 1975 and 1985, and, although some research has continued since, it has not been on the scale of the formative years. Supported by the National Cricket Association (NCA), the majority of the work was undertaken by Nottinghamshire County Council, in conjunction with Nottinghamshire County Cricket Club, who developed, amongst others, the first portable pitch which enabled Floodlit cricket matches to be played in football stadia in the 1980s.

The NCA first introduced the NTP Pitches Approval Scheme in the early 1990s. Six pitch systems were originally approved, but one was taken off the market.

Pitch approvals last for five years after which the companies must reapply. It is important to bear in mind that it is the pitch system that is approved and not the company supplying the pitch.

The first Performance Specification for Artificial Cricket Pitches was introduced by the Sports Council in 1984, having been developed by a consortium comprising of RAPRA Technology, suppliers of cricket surfaces, many individual experts and the NCA. The work started in 1977 and was completed in 1980. The NCA updated the specification in 1987 and introduced the NCA Performance Specification in 1990. Since then it has been updated a number of times, taking into account the research projects carried out at Lilleshall National Sports Centre and the NCA match pitch programme for the installation of pitches in the 1990s. An updated version of the specification, ‘The Standard’, was introduced in 2000. The latest version, entitled ECB Performance Standards for Non-Turf Cricket Pitches Intended for Outdoor Use (TS6) was produced in Nov 2007.

In addition to the many systems sold in the UK, pitches have been exported to New Zealand, West Indies, Sri Lanka, India, Pakistan, South Africa, Holland, France, Spain, Canada, United States, Ireland and others.

The ECB Approvals System has been constantly updated and is now used to ensure that pitches which have been shown to meet the requirements of “The Standard” are installed. This is important where financial grants are involved. The supplier of an approved pitch system must provide evidence of:

In addition, the introduction of the ‘ECB Employer’s Requirements’ provided a framework for the procedures involved in installing a pitch or facility.

Non-turf pitches can be divided into two main groups – Bound & Unbound.

Bound is where the surfaces are laid on a structure bound together by a bonding agent like Bitmac.

Unbound is where the surfaces are laid on a structure that is not bound and held together by the particles’ interlocking and particle size distribution.

Unbound has the ability to absorb moisture and alter the playing characteristic of a pitch more readily than a bound structure. Therefore, it plays similarly to a good natural turf pitch with changeable playing characteristics influenced by the moisture content in the base formation.

This information should only be used as a generalisation as designers may have their own method of meeting the ECB Performance Standard and providing a pitch that plays like grass.

There are several designs which have been shown to meet the criteria as laid down within the ECB Standard but may not be an approved ECB system. Therefore, they would not be recommended by ECB.

Research has shown designers may adjust the performance of a pitch by adjusting any one of the following:

Earlier pitches required a pile length of no greater than 6 mm as in the earlier days. The longer the pile, the more the playing characteristic were affected. This is no longer applicable with recent surface introductions as long as the pile does not flatten significantly. During the past 25 years, practical research has shown that the top 100 mm of a non-turf pitch influence playing performance. The ability of this zone to absorb moisture is a major factor in determining how a pitch plays.

The number and depth of moisture-absorbing components in the zone affect the extent to which a pitch performs, thereby providing the nearest comparison to a grass pitch. However, the combination of components and the extent to which they are affected by moisture determine “the changeability” in a pitch, in the same way a grass pitch is affected.

Based on the ability of the structure to absorb or be affected by moisture, the playing performance of a pitch is classified as either totally dynamic, semi-dynamic, totally static or semi-static.